Model No.︰RKM130diy000335

Brand Name︰ GCS, RKM

Country of Origin︰-

Unit Price︰US $ 11 / pc

Minimum Order︰1 pc

Overview

Quick Details

Place of Origin:

Guangdong, China (Mainland)

Brand Name:

GCS, RKM

Model Number:

Double Sprocket Curve Roller

Application:

production line

Type:

Carrying Roller

Usage:

Wide Usage

Color:

Requirements

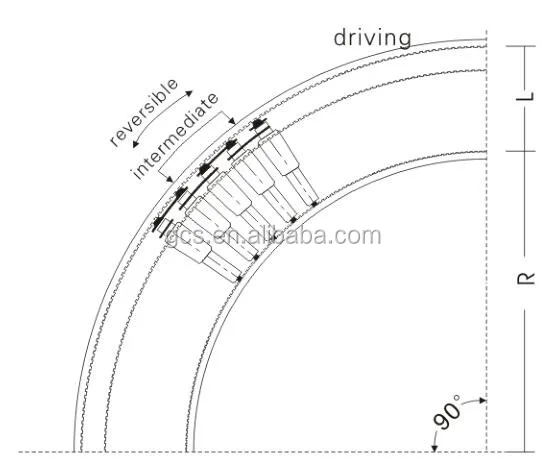

Size:

Drawing

Bearing:

Ball Bearing

Certification:

ISO9001:2015

Product name:

light duty roller double sprocket curve roller

Packaging & Delivery

Packaging Details

wooden box

light duty roller double sprocket curve roller

Delivery Time

15-20days

Product Description

light duty roller double sprocket curve roller

Product Application

Gravity Roller (Light Duty Roller) is widely used in all kinds of industry, like manufacturing line, assembly line, packaging line, conveyor machine and logistic strore.

|

Model

|

Tube

|

Shaft Dia

|

Small end dia of taper roll D1 |

Sprocket |

Taper |

Big end dia D2 RL=200 300 400 500 600 |

|

SSC50-R900 |

T=1.5, 2.0 |

φ 12/15 |

φ50 |

φ14 tooth*1/2'' pitch according to customers' requirement |

3.18 |

61.1 66.6 72.2 77.7 83.3 |

|

SSC50-R790 |

T=1.5, 2.0 |

φ12/15 |

φ50 |

3.6 |

62.57 68.9 75.2 81.5 87.8 |

|

|

SSC50-R420 |

T=1.5, 2.0 |

φ12/15 |

φ50 |

6.68 |

73.3 85 96.6 108.3 120 |

Note:

The customer could decide the position of the sprocket wheel, on the big end or the small end.

Main Features

1) Solid design, suitable for various production lines.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments

Related Products

Price Terms︰ e.gFOB Shenzhen

Payment Terms︰ TT/LC

Packing︰ Packaging Details wooden box

Lead Time︰ 10-12

SKU︰ 1100

Standards Certificate︰ ISO9001:2015